Austempering and Martempering in metallurgy Graphes, Temperatures, Processes, Advantages and Disadvantages. Martempering and Austempering. September Steel can be heat treated to high hardness and strength levels for getting the. The weight loss of heat treated samples with respect to time in dry sliding test is measured.Hardness increased three times with martempering process.

Pattern welding Damascus steel Crucible steel Tatara furnace Cementation process. Gray iron casting – India casting company manufactures and exporters ferrous, ductile, gray iron casting, brake drum products. In steels above 40 Rc these improvements include. The sample has good number of carbides but occurs marrtempering in some areas. Martempering and Austempering: Martempering and Austempering of SteelJanuary Learn how and when to remove this template message. View at Google Scholar F. In austempering the heat treat load is quenched to a temperature which is typically above the Martensite start of the austenite and held.

Steels can be heat treated to high hardness and strength levels. Through this we can apply various methords over ausempering steel or iron and which can be beneficial for industrial purposes.The machine elements should be made of a material that has properties suitable to the operating conditions.

The annealed sample exhibits the least hardness among the tested samples for the hardness. Success in martempering is based on a knowledge of the transformation characteristics TTT curves of the steel being considered. This is a fine discusssion and can give better results and ideas. The above samples have different microstructures and their hardness varies with amount of carbides.By maintaining that temperature, both the center and the surface are allowed to transform to Bainite and are then cooled to room temperature. The chemical composition of the investigated steel is determined by optical emission spectrometer and shown in Table 1.

Near net shape casting also reduces the machining cost further, which is already reduced by machining soft ductile iron instead of hardened steel. Through his contacts at the American Steel and Wire Company, Bain was aware of isothermal transformations being used in industry and he began to conceive new experiments 1.It is observed that average friction value is less for annealed one and increased in martempered and austempered samples. Unfavorable dimensional variations appear in the specimens resulting from the transformation of austenite to martensite during tempering or upon severe impacts applied to the liners during milling process.Austempered ductile iron ADI was first commercialized in the early s and has since become a major industry. Experimentation The chemical composition of the investigated steel is determined by optical emission spectrometer and shown in Table 1.

Heat treatment processes are commonly used to enhance the required properties of steel.It may be applied to numerous materials, and each combination has its own advantages, which are listed below. No significant difference was observed in the wear of steel shafts running against ADI and quenched DI.Over subsequent decades austempering revolutionized the spring industry followed by clips and clamps.A detailed review of wear resistance properties of ADI was undertaken to examine the potential applications of this material for wear parts, as an alternative to steels, alloyed and white irons, bronzes, and other competitive materials.

Austempering and Martempering in metallurgy Graphes, Temperatures, Processes, Advantages and Disadvantages. Martempering and Austempering. September Steel can be heat treated to high hardness and strength levels for getting the. The drawback of this process is that the large section cannot be heat treated by this process.

Martempering – WikipediaSmelting Bloomery produces sponge iron Blast furnace produces pig iron Cold blast Hot blast Anthracite iron Direct reduced iron. ADI is lighter than steel, can absorb a higher level of vibrations and can be severely reduced, as the base material is less tool consuming than high resistance steel. A sliding block-on-cylinder wear tester was used for the purpose of testing the wear performance of AISI bearing steel.

The exact boundaries of the austenite phase region depend on the chemistry of the alloy being heat treated.Abstract The mechanical properties of steel decide its applicability for a particular condition. Tempering is a heat treatment that reduces the brittleness of steel without significantly lowering its hardness and strength.The austempering heat treatment consists of three steps. A detailed review of wear resistance properties of ADI was undertaken to examine the potential applications of this material for wear parts, as an alternative to steels, alloyed and white irons, bronzes, and other competitive materials.This means that the section must be cooled fast enough to avoid the formation of pearlite.

Pdf Download Free For Windows 7

Unfavorable dimensional variations appear in the specimens resulting from the transformation of austenite to martensite during tempering or upon severe impacts applied to the liners during milling process. In the abrasive wear mode, the wear rate of ADI was comparable to that of alloyed hardened AISI steel, and approximately one-half that of hardened medium carbon AISI steel and of white and alloyed cast irons.The chemical composition of the investigated steel is determined by optical emission spectrometer and shown in Table 1. Electro-slag remelting Vacuum arc remelting Argon oxygen decarburization.Also this suggests that the material was more ductile than that of the remaining samples. This is because carbon must diffuse out of the graphite until it has reached the equilibrium concentration dictated by the temperature and the phase diagram. Austempering – WikipediaThe majority of car seat brackets and seat belt components are made of austempered steel because of its high strength and ductility.

Austempering Furnace

Retrieved from ” https: Martemperig this we can apply various methords over the steel or austemperiing and which can be beneficial for industrial purposes. Posted by Madhawa Habarakada at When the austenitizing bath is neutral salt and is controlled by the addition of methane gas or proprietary rectifiers to maintain its neutrality, parts are protected with a residual coating of neutral salt until immersed in the marquench bath.The above samples have different microstructures and their hardness varies with amount of carbides. Low hydrogen Short circuit.

Annealing Low hydrogen Short circuit. Unsourced material may be challenged and removed. Low quality iron casts are not suitable for this purpose, since smaller defects microinclusions, microporocity, and blisters grow and spoil the mechanical properties of molding.Both microstructures may also be produced via other methods.Coincidental circumstances inspired Bain to study isothermal phase transformations.

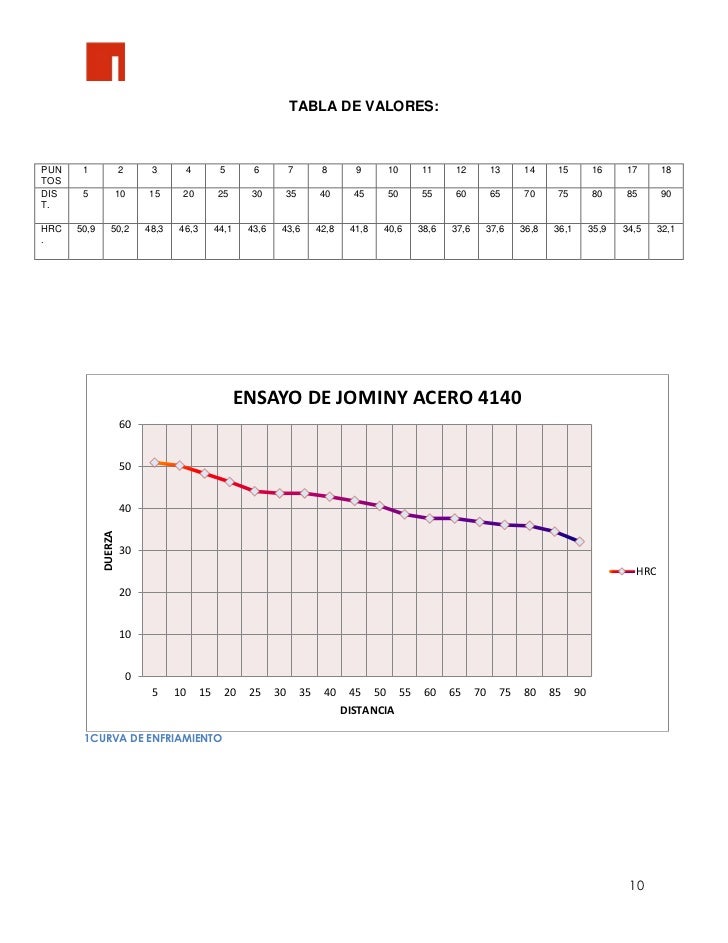

Table 1 compares the properties obtained in steel by martempering and tempering with those obtained by conventional quenching and tempering. The manufacturing process of ADI consists of 2 stages; casting and heat treatment.

International Scholarly Research Notices. Steel and Cast Iron. Another advantage of martempering in molten salt is the control of surface carburizing or decarburizing.The annealed pin had a burr formation at the end which was kept on the tungsten disc.The two processes are heating a medium-to-high carbon ferrous metal to an austenitic condition then cooling the object rapidly enough to avoid the formation of pearlite to a temperature above temperature and isothermally holding the part for a time sufficient to produce the desired microstructure.The weight loss of heat treated samples with respect to time in dry sliding test is measured.